Interesting facts about cork

Cork has a long history. Below we present 6 interesting facts about cork that will allow us to learn more about cork, an environmentally friendly and innovative material.

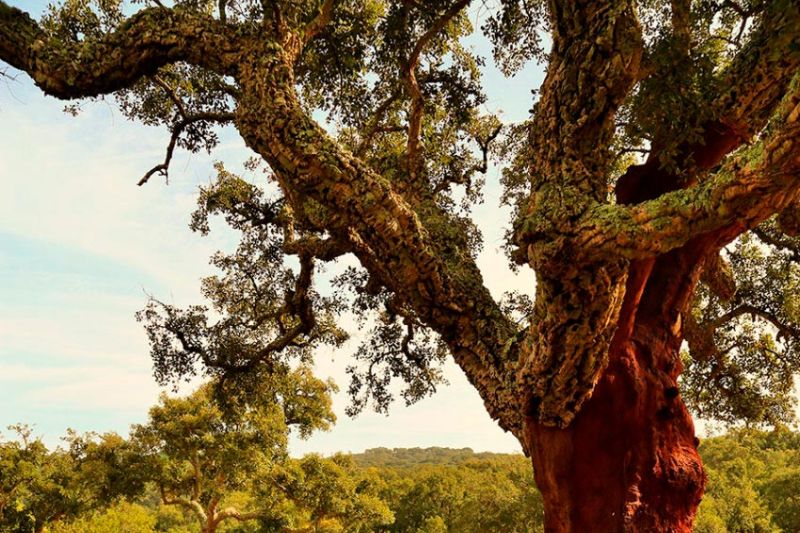

The largest and oldest cork oak in the world is known as Assobiador (Whistler). The name was inspired by the sound of songbirds falling on tree branches. The cork oak, planted in 1783, is over 14 meters high and has a trunk circumference of 4.15 meters.

During the 2010 NATO summit, celebrities such as Barack Obama, Angela Merkel and Hillary Clinton received gifts in the form of cork fashion and accessories. The US president also received a collar for his Portuguese water dog, Bo.

Hollywood uses cork to imitate the remains of explosions. Cork was used in the films “Ghostbusters” and “Mission Impossible”.

The Portuguese cork closes the most expensive whiskey in the world, Dalmore Trinitas 64, which costs 118,000 euros per bottle.

The floor of the Sagrada Familia cathedral in Barcelona was made of cork to improve acoustics and prevent hypothermia.

No trees are destroyed during the production of cork. After harvesting, the cork oak undergoes a self-regeneration process that cannot be observed in any other species.