Cork in the winter garden

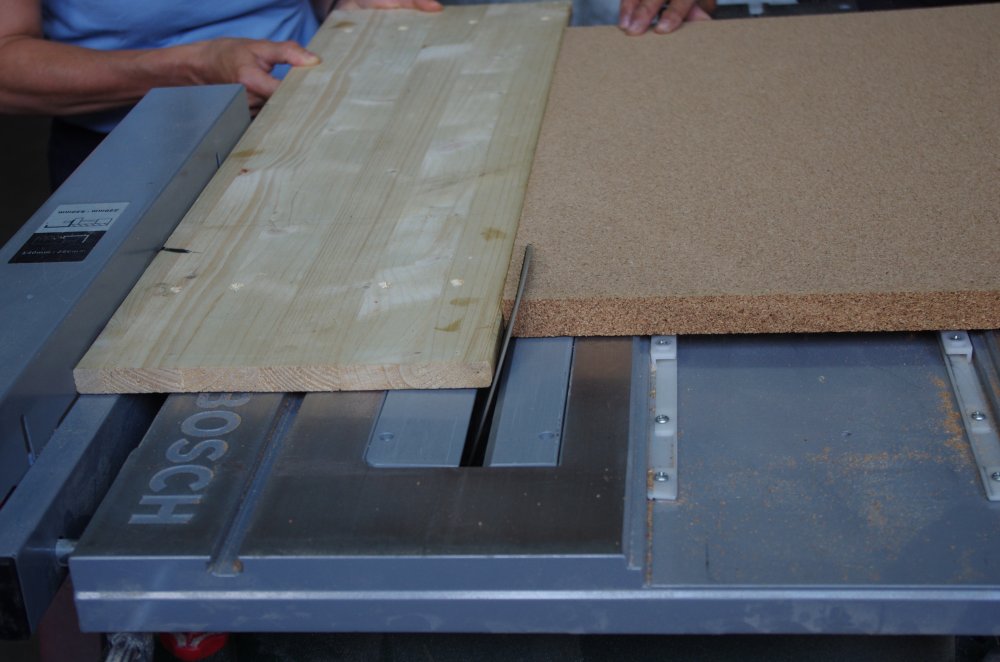

If you live in a glass house or have a second living room where you feel like outside all year round, you should think about using cork parquet or panels in it! The tiles for the conservatory should also perfectly harmonize with its home atmosphere.

After all, tiles for the winter garden or other floor coverings must not only be aesthetic, but also meet functional requirements. The floor covering must be able to withstand the extreme temperature fluctuations in the conservatory.

Cork tiles make the room cozy and easy to clean. They meet high requirements where not every floor covering will work. If it gets cold in the winter garden, ordinary parquet or laminate will not work as well as a cork floor.

Traces of water can damage the floor and frost damage cannot be ruled out. Carpet for the conservatory is not so durable and easy to clean.

PVC floors as they can quickly become slippery when wet. Cork floors come in the form of panels and cork parquet and are laid or glued to the floor. It is a natural material, it perfectly insulates thermally and acoustically and is friendly to people allergic to house dust.

The care of a cork floor is similar to that of wooden floors. Regular sealing with wax is recommended so that it is not exposed to climatic influences