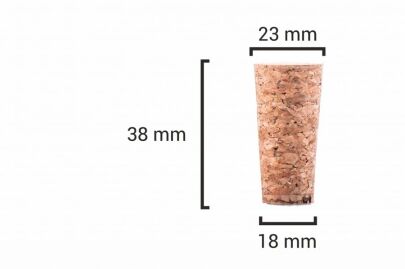

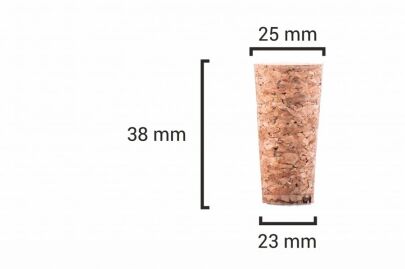

In our store's assortment you will find cork stoppers for bottles in various shapes and for many other uses. We have both cork stoppers for wine and stoppers with a dispenser, which can be used, for example, for a bottle of oil. Glass test tubes with a cork stopper are great for storing spices or, after filling with dried flowers, can serve as an original wedding gift. Round stoppers, on the other hand, will be a good alternative to the caps of larger glass containers. Cork balls, on the other hand, can be used to create an original key chain or as a carafe cap.